Best solution for flat roof: Top 5 Ultimate Options

Why Choosing the Best Solution for a Flat Roof Matters

Finding the best solution for a flat roof is critical because these systems face a unique barrage of challenges that sloped roofs do not, including water pooling, intense UV degradation, membrane shrinkage, and physical damage. Unlike a pitched roof that uses gravity to shed water quickly, a flat roof’s performance relies entirely on the integrity of its waterproofing membrane and the precision of its drainage design. A single flaw, seam failure, or puncture can lead to catastrophic water intrusion and costly interior damage to inventory, equipment, and structural components. For property owners seeking durable, long-term, and energy-efficient protection, our roofing specialists in Sugar Land provide expert guidance custom-tailored to the demanding Texas climate.

The relentless Texas sun bombards roofs with UV radiation, accelerating material aging, while sudden, violent thunderstorms and hailstorms test their impact resistance and seam integrity. The dramatic temperature swings between day and night cause constant expansion and contraction, a phenomenon known as thermal shock, which can stress seams and lead to premature failure. Choosing the right material is an investment in resilience against these forces.

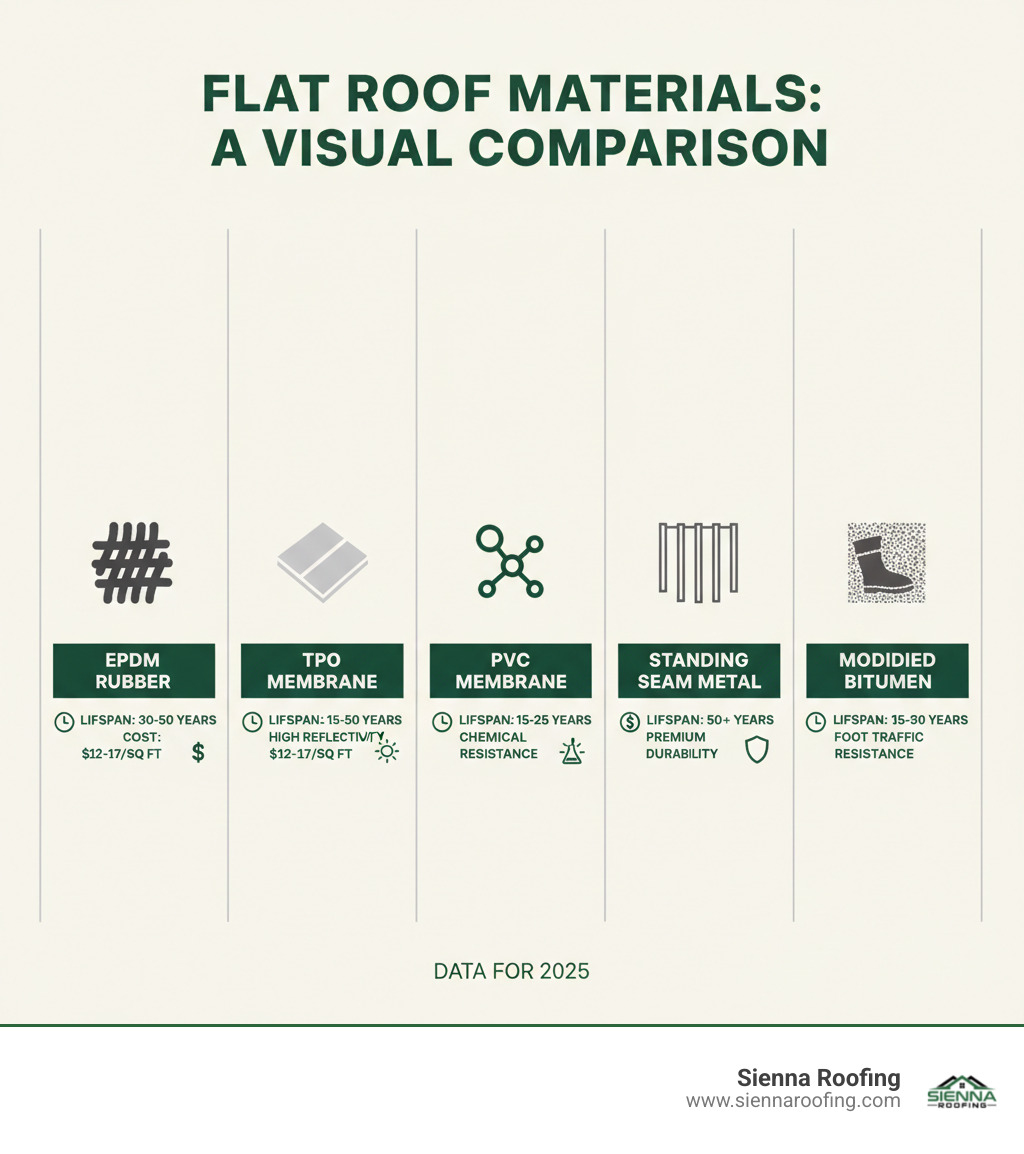

The top-performing options each offer distinct advantages:

| Material | Lifespan | Best For | Key Advantage |

|---|---|---|---|

| EPDM Rubber | 30-50 years | Budget-conscious projects | Proven durability at lower cost |

| TPO Membrane | 15-25 years | Energy efficiency | Reflects up to 80% of solar heat |

| PVC Membrane | 20-30+ years | Chemical resistance | Superior puncture and fire resistance |

| Standing Seam Metal | 30-50+ years | Maximum longevity | Lowest maintenance, highest upfront cost |

| Modified Bitumen | 15-20 years | High foot traffic | Excellent tear resistance |

In Texas, where 100°F+ temperatures and severe storms are common, the right material can last up to 50 years and cut energy costs by 30%. This guide provides data-backed comparisons to help you navigate modern single-ply membranes, traditional multi-layer systems, and premium metal roofing, ensuring you make an informed decision that protects your asset for decades.

I’m Andre Castro, founder of Sienna Roofing & Solar. With hundreds of flat roof installations across the Houston Metro area, my team and I help property owners find solutions that protect their investments for decades.

Section 1: A Data-Driven Comparison of Flat Roof Materials

Choosing the best solution for a flat roof requires a detailed analysis of lifespan, cost, energy efficiency, and resilience against specific environmental threats. Industry data shows the right material can extend your roof’s life by up to 50 years and slash energy bills by 30% or more. Here’s a comprehensive breakdown of how the leading materials compare, followed by a deeper dive into each system.

| Material | Average Lifespan (Years) | Estimated Cost per Sq. Ft. | Energy Efficiency (Reflectivity) | Puncture Resistance |

|---|---|---|---|---|

| EPDM (Rubber) | 25-50 | $12.00 – $17.00 | Low (Black, high heat absorption) | Moderate |

| TPO (Thermoplastic) | 10-25 | $12.00 – $17.00 | High (White, high reflectivity) | Moderate |

| PVC (Thermoplastic) | 20-30 | $12.00 – $17.00 | High (White, high reflectivity) | Good |

| Modified Bitumen | 15-20 | $4.00 – $13.00 | Moderate (Can be reflective) | Good |

| Built-Up Roof (BUR) | 15-30 | $4.00 – $13.00 | Moderate (Gravel surface) | High |

| Standing Seam Metal | 30-50+ | $15.00+ | High (Can be reflective) | Excellent |

Single-Ply Membranes: The Modern Standard

Single-ply membranes represent the largest share of the commercial roofing market due to their cost-effectiveness, flexibility, and efficient installation. They are manufactured in a factory-controlled setting and installed in large sheets, which minimizes the number of seams—the most common point of failure in any roofing system.

- EPDM (Ethylene Propylene Diene Monomer): This synthetic rubber membrane is a time-tested workhorse, with some of the earliest installations still performing well after 40+ years. Its exceptional flexibility and elongation properties allow it to handle extreme temperature shifts and building movement without cracking. EPDM is available in various thicknesses (typically 45, 60, and 90 mil) and can be installed in three ways: fully adhered (glued down), mechanically fastened, or ballasted (held down with gravel or pavers). While its standard black color absorbs heat and increases cooling costs, white-surfaced EPDM is now available to provide better solar reflectivity, though it comes at a higher cost.

- TPO (Thermoplastic Polyolefin): As the fastest-growing segment of the single-ply market, TPO is a popular choice for energy-conscious building owners. Its brilliant white surface reflects up to 80% of solar heat, significantly reducing cooling loads. The seams are welded together with hot air, fusing them into a single, monolithic sheet that is exceptionally strong and leak-resistant. Lifespan is typically 10-25 years, but it’s crucial to note that quality can vary significantly between manufacturers. To ensure durability, look for TPO membranes that meet or exceed the ASTM D6878 standard for material quality and are reinforced with a polyester scrim for superior tear and puncture resistance.

- PVC (Polyvinyl Chloride): As a premium single-ply option, PVC offers superior resistance to chemicals, grease, oils, and fire, making it the ideal choice for restaurants, airports, and industrial facilities with rooftop exhaust vents. Like TPO, its seams are heat-welded for maximum strength. PVC is highly reflective, durable, and has a proven lifespan of 20-30+ years. While its upfront cost is higher than TPO or EPDM, its exceptional resistance to harsh chemicals and punctures provides long-term value in demanding environments.

Asphalt-Based & Multi-Layer Systems: The Tried-and-True Options

These traditional systems offer robust, multi-layer protection, providing redundancy that single-ply membranes lack.

- Modified Bitumen (Mod-Bit): This is an evolution of traditional asphalt roofing. The asphalt is modified with polymers—either APP (Atactic Polypropylene) for enhanced UV resistance and durability or SBS (Styrene-Butadiene-Styrene) for superior flexibility and elasticity. It is typically installed in two or three-ply systems, providing excellent tear resistance and durability, making it ideal for roofs with high foot traffic or heavy equipment. While traditional torch-down application carries fire risks and requires a highly skilled crew, modern cold-process adhesives and self-adhered sheets offer a safer and equally effective installation method. Lifespan is generally 15-20 years.

- Built-Up Roof (BUR): For over a century, BUR systems have offered exceptional water and UV protection. They are constructed on-site with alternating layers of bitumen (asphalt) and reinforcing fabrics (plies), topped with a layer of gravel, slag, or a mineral-surfaced cap sheet. This multi-layer construction creates tremendous redundancy; a minor defect in one layer is backed up by others. The aggregate surface provides outstanding UV protection and Class A fire resistance. However, these systems are extremely heavy, often requiring a structural assessment, and their installation is labor-intensive and messy. Furthermore, tracing the source of a leak can be very difficult.

Standing Seam Metal: The Ultimate in Longevity

Standing seam metal is the premium choice for low-slope roofing, delivering unmatched longevity and durability. Panels of 22 or 24-gauge steel or aluminum are joined by raised, interlocking seams that are mechanically crimped, concealing the fasteners from the elements. This design eliminates thousands of potential leak points created by exposed screws. A properly installed standing seam metal roof can last 50 years or more with minimal maintenance, offering superior resistance to fire, wind uplift, and hail—all common threats in Texas. While the upfront cost is the highest (starting at $15.00+ per sq. ft.), its incredible lifespan, low maintenance needs, and recyclability often make it the most economical choice over the total life of the building.

Section 2: Key Factors That Determine the Best Flat Roof Solution

Choosing the best solution for a flat roof goes beyond simply picking a material from a chart; it requires a holistic approach that matches the system to your building’s specific function, local climate, and structural capacity. In the Houston area, from the urban heat island of downtown to the sprawling commercial parks in Sugar Land and Missouri City, these factors are critical for ensuring long-term performance and maximizing your return on investment.

Climate and Energy Efficiency

In Texas, your roof is a primary driver of your building’s energy budget. Cool roofing materials like white TPO, PVC, and specialized coatings can reduce cooling costs by up to 20% by reflecting the sun’s thermal energy. The effectiveness of these materials is measured by the Solar Reflectance Index (SRI), a scale from 0 to 100 that combines reflectivity (how much solar energy is reflected) and thermal emittance (how efficiently a surface releases absorbed heat). A higher SRI value means a cooler roof. You can verify the energy performance of different roofing products through the independent Cool Roof Rating Council (CRRC), which maintains a public database of rated products. For areas with extreme temperature swings, EPDM’s flexibility prevents cracking, while impact-resistant options like SBS Modified Bitumen and standing seam metal offer superior protection against the frequent hailstorms that plague the region. A building in urban Sugar Land faces different conditions than one in open Richmond; our Sugar Land roofing insights explore these local nuances.

Building Use and Foot Traffic

Consider what happens on your roof. Is it merely a cover, or is it a platform for heavy HVAC units, industrial exhaust fans, or solar panel arrays? A roof supporting heavy equipment needs high puncture and abrasion resistance, making robust systems like multi-ply Modified Bitumen or BUR an excellent choice. For single-ply roofs, installing designated walkway pads is essential to protect the membrane from damage caused by dropped tools, screws, and repeated foot traffic from maintenance personnel. These pads are made from thick, durable, and often textured materials (like reinforced PVC or rubber) that are heat-welded or adhered over the primary membrane, creating a sacrificial path that preserves the waterproofing layer underneath.

Insulation and Slope: The Unsung Heroes

A common and dangerous misconception is that flat roofs are perfectly flat. In reality, they must have a slight slope to ensure positive water drainage and prevent ponding, which is the primary cause of leaks, material degradation, and premature failure. Industry best practice and building codes mandate a minimum slope of ¼ inch per foot. This critical slope is typically created using a tapered insulation system. High-performance rigid foam insulation boards (most commonly Polyisocyanurate, or “Polyiso”) are custom-cut at the factory into angled panels. When installed in a specific layout, they create a gentle slope that directs water efficiently toward drains and scuppers. This system serves two vital functions: it guarantees drainage and dramatically improves a building’s thermal performance. High-quality insulation can improve a building’s R-value by up to 40%, lowering energy bills year-round and protecting the roof membrane from extreme temperature fluctuations. The insulation and underlayment are the unsung heroes of a durable, energy-efficient flat roof system.

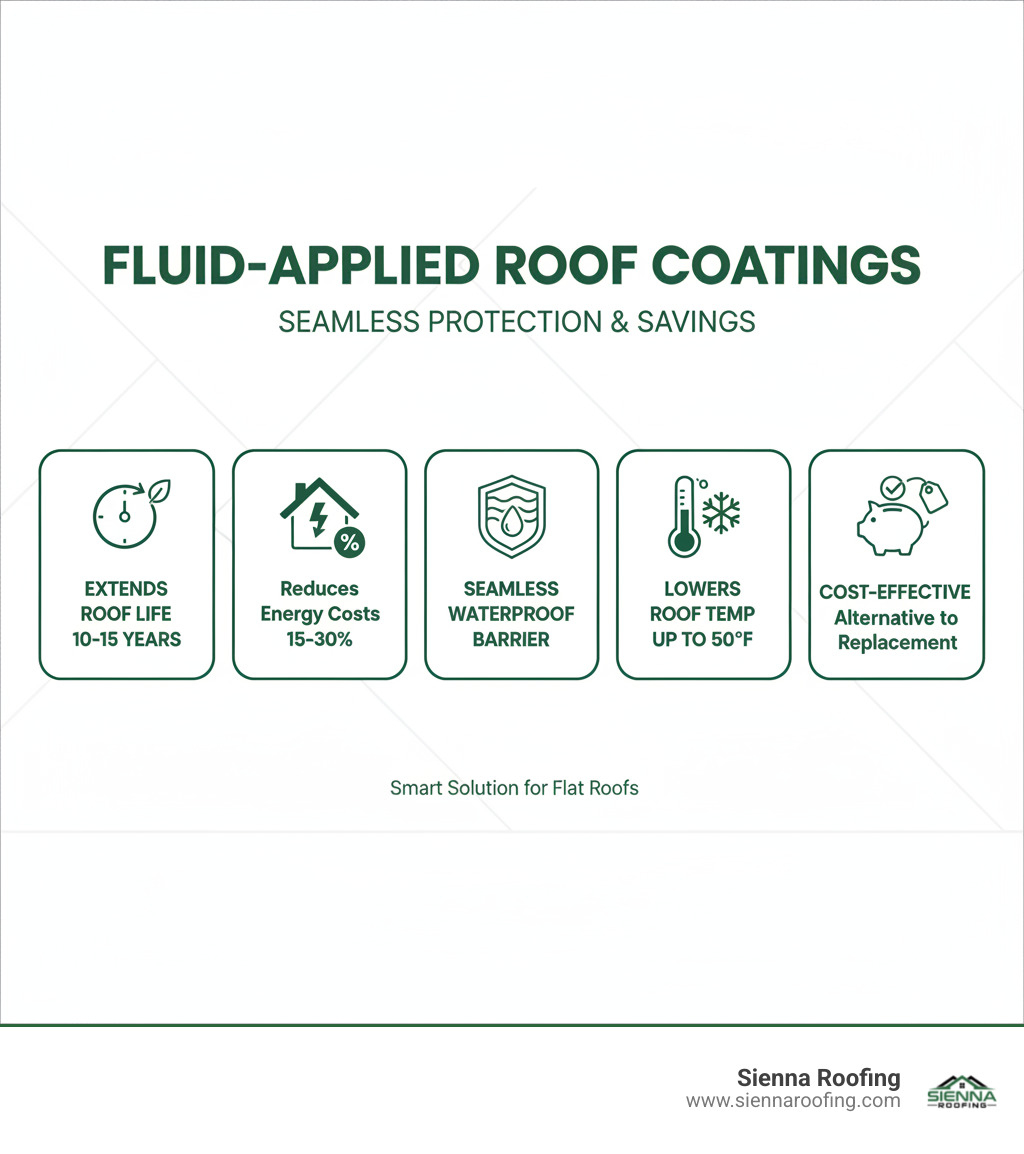

Section 3: Restoration vs. Replacement—A Smart Financial Choice

When your flat roof shows signs of aging, leaks, or surface wear, a complete and costly tear-off and replacement isn’t your only option. If a professional inspection confirms the underlying structure and insulation are sound and dry, roof restoration can extend its life by 10-20 years at 50-70% of the cost of a full replacement. This approach is an incredibly valuable financial strategy for commercial properties in the Houston area, as it minimizes operational disruptions, avoids landfill fees, and can often be categorized as a maintenance expense for tax purposes rather than a capital expenditure.

Fluid-Applied Roof Coatings for Seamless Protection

Fluid-applied coatings, most commonly silicone, acrylic, or urethane, are engineered to create a seamless, monolithic, and waterproof barrier directly over your existing roof. They are sprayed or rolled on as a liquid, allowing them to flow into every crack, crevice, and around complex penetrations, sealing minor imperfections and creating a brand-new protective layer.

The benefits are significant:

- Energy Savings: Highly reflective white coatings can lower roof surface temperatures by up to 50-80°F, significantly reducing cooling energy consumption by 15-30% in the brutal Texas heat. This lessens the strain on HVAC units, extending their service life.

- Extended Lifespan: A properly installed coating system can add 10 to 20 years of service life to your existing roof, stopping active leaks, sealing seams, and preventing further UV degradation of the original membrane.

- Sustainability: Restoration is an environmentally responsible choice. It minimizes landfill waste by preserving the existing roof system and its embodied energy, reducing the environmental impact of your building.

However, a coating is only as good as the surface it’s applied to. A successful restoration requires meticulous preparation. The process must include: 1) a thorough inspection, including core samples or an infrared scan to verify the insulation is dry; 2) intensive cleaning with high-pressure washing to remove all dirt and contaminants; 3) detailed repairs to all seams, flashings, and damaged areas; and 4) application of a specialized primer to ensure tenacious adhesion. For property owners seeking the best solution for flat roof preservation without the high cost and disruption of replacement, a professionally installed coating system offers an intelligent and cost-effective path forward.

Why Professional Installation is Non-Negotiable

Flat roofing, whether a new installation or a restoration, is a technical discipline that is absolutely not a DIY project. It demands deep expertise to ensure watertight seams, proper flashing details around walls and penetrations, and correct material application according to strict manufacturer specifications. A single mistake—an improperly welded TPO seam, a poorly terminated flashing at a parapet wall, or using the wrong fasteners for the roof deck—can lead to catastrophic leaks and will instantly void expensive manufacturer warranties. Materials like spray polyurethane foam (SPF) and certain coatings require precise temperature controls, humidity monitoring, and application techniques that only certified, experienced professionals possess.

At Sienna Roofing, our certified installers guarantee every project complies with manufacturer standards and local building codes. Our deep, hands-on understanding of how the Houston climate affects material behavior during installation ensures your investment is protected for decades, whether it’s a full replacement or a life-extending restoration.

Section 4: How to Choose a Qualified Flat Roofing Contractor

The most advanced roofing material in the world will fail if installed improperly. The performance, longevity, and warranty of your roof are all directly tied to the quality of your contractor. Choosing the right partner is the most important first step toward achieving the best solution for a flat roof.

Here’s what to look for in a qualified flat roofing contractor:

- Licensing and Insurance: This is the absolute baseline for consideration. The contractor must hold all required state and local licenses. Crucially, ask for a certificate of insurance verifying both general liability coverage (a minimum of $1 million is standard for commercial work) and worker’s compensation. This protects you from all liability in the event of an accident on your property.

- Specialized Flat Roof Expertise: Flat roofing is a specialty. A general residential roofer who primarily installs shingles likely lacks the specific skills and equipment required for low-slope systems. Ask for a portfolio of recently completed flat roof projects similar to yours. Inquire if they are certified installers for major manufacturers like Carlisle, GAF, Firestone, or Johns Manville. These certifications prove their crews have been professionally trained and tested on the specific installation requirements for those materials.

- Strong Local Reputation: Check online reviews on Google, Yelp, and the Better Business Bureau. More importantly, ask for local references for projects completed 3-5 years ago. This allows you to see how their work holds up over time. A contractor’s long-standing reputation in communities like Sugar Land and Missouri City speaks volumes about their commitment to quality and customer service.

- Transparent, Written Estimates: A professional provides a detailed, itemized proposal that clearly outlines the scope of work, specific materials to be used (including brand and thickness), labor costs, tear-off and disposal fees, and project timelines. Vague, one-page estimates are a major red flag.

- Comprehensive Warranties: Understand the warranties offered. There are two types: the contractor’s workmanship warranty (typically 1-5 years, covering installation errors) and the manufacturer’s system warranty (often 15-30 years). The best manufacturer warranties, known as NDL (No Dollar Limit) warranties, cover both materials and labor for repairs and require installation by a certified contractor and a final inspection by a manufacturer’s representative. Ensure you receive both in writing.

- Proactive Maintenance Plans: The best contractors don’t just disappear after the job is done. They offer proactive maintenance programs to protect your investment. These plans should include semi-annual inspections, cleaning of drains, gutters, and scuppers, removal of debris, and minor repairs to seals and caulking to catch small issues before they become major problems.

Ready to work with a trusted local expert who checks all these boxes? Contact our team at Click to Call: (832) 772-6522 for a detailed assessment and a transparent quote.

Section 5: Frequently Asked Questions About Flat Roofs

Here are expert answers to the most common questions we receive from property owners in the Houston metropolitan area.

What is the most durable flat roofing material?

For sheer longevity and resistance to physical damage, Standing Seam Metal roofs are the most durable option, with a lifespan that can exceed 50 years and superior resistance to fire, wind, and hail. For roofs that must endure high foot traffic or have a large amount of heavy equipment, multi-layer systems like a 2-ply Modified Bitumen or a traditional Built-Up Roofing (BUR) system offer excellent puncture and abrasion resistance due to their thickness and redundancy.

How do flat roof materials differ in energy efficiency?

Energy efficiency varies significantly and is a major cost factor in Texas. It’s measured by the Solar Reflectance Index (SRI):

- High Efficiency (Cool Roofs): White TPO and PVC membranes, along with white acrylic or silicone roof coatings, can have high SRI values. They reflect up to 80% of solar heat, dramatically lowering roof surface temperatures and reducing HVAC cooling costs.

- Moderate Efficiency: Modified Bitumen with reflective granules, specially coated Standing Seam Metal, and white EPDM offer good reflectivity and can contribute to energy savings.

- Low Efficiency: Standard black EPDM and dark-colored BUR with a gravel surface absorb a significant amount of heat, increasing the building’s cooling load. They are less ideal for air-conditioned spaces in hot climates like Texas.

What are the potential drawbacks of each material?

Every material has trade-offs, and understanding them is key to selecting the best solution for a flat roof:

- EPDM: Prone to punctures, and its standard black color absorbs heat. Seams are glued, which can be a point of failure over time compared to heat-welded seams.

- TPO: Quality varies significantly by brand, and some earlier formulations had issues with premature aging. The white surface shows dirt easily.

- PVC: Higher upfront cost compared to TPO and EPDM. Can become brittle in extremely cold climates, though this is less of a concern in Houston.

- Modified Bitumen: Shorter lifespan than single-plies or metal. Torch-down application carries significant fire risks if not performed by an expert crew.

- Built-Up Roof (BUR): Extremely heavy, often requiring structural reinforcement. Installation is messy and labor-intensive, and leaks are very difficult to locate.

- Standing Seam Metal: Highest upfront cost of any system. Requires highly specialized installation expertise to manage thermal expansion and contraction correctly.

How much does a new flat roof cost?

Costs are highly variable, but here are general, all-in estimates for professionally installed systems:

- Membrane Roofs (EPDM, TPO, PVC): $12.00 – $17.00 per square foot.

- Modified Bitumen/BUR: $4.00 – $13.00 per square foot.

- Standing Seam Metal: $15.00+ per square foot.

Factors that significantly affect the final price include the amount of insulation required, whether a full tear-off of the old roof is necessary, the complexity of the roof (number of penetrations), and the type of warranty selected.

What are the most common signs of flat roof failure?

Be vigilant for ponding water that remains for more than 48 hours after rain, as this indicates a drainage problem. Also look for visible cracks, blisters, or alligatoring (interconnecting cracks) in the membrane surface, open or separating seams, and any water stains appearing on interior ceilings or walls.

How often should a commercial flat roof be inspected?

A flat roof should be professionally inspected at least twice a year, typically in the spring and fall, to prepare for summer heat and winter cold. It should also be inspected immediately after any major weather event, such as a hurricane or hailstorm. These inspections allow for the cleaning of debris from drains and the early detection of minor issues before they escalate into costly leaks.

Can you install solar panels on a flat roof?

Absolutely. Flat roofs are ideal for solar panel installations because they allow for the use of ballasted or attached racking systems that can be oriented at the perfect angle and direction to maximize energy production. As a roofing and solar company, Sienna Roofing specializes in designing and installing integrated roof and solar systems, ensuring that the solar array is mounted securely without compromising the integrity of the waterproofing system.

Conclusion: Secure the Best Flat Roof Solution for Your Property

Your flat roof is a critical asset that protects your entire business operation. As we’ve detailed, the best solution for a flat roof is never a one-size-fits-all product. It’s a customized system that balances the right material, a professionally designed tapered insulation and drainage plan, and meticulous installation to withstand the unique challenges of the Texas climate.

We’ve covered how reflective TPO and PVC offer superior energy efficiency, how robust Modified Bitumen handles heavy foot traffic, and how standing seam metal provides ultimate longevity. We’ve also shown how a professionally installed restoration coating can be a smart financial alternative to a full replacement, extending the life of your current roof at a fraction of the cost.

For property owners in Sugar Land, Missouri City, and the greater Houston area, making the right choice means partnering with a true specialist. At Sienna Roofing, we don’t just sell roofs—we provide honest, data-driven recommendations tailored to your building’s use, structural needs, and long-term financial goals. Our commitment to manufacturer-certified installation, proactive maintenance, and a 100% satisfaction guarantee means you’re partnering with a team that is invested in protecting your property for the long haul.

Ready to find the perfect, long-term flat roof solution? Contact our expert team at Click to Call: (832) 772-6522 or learn more about our specialized Flat Roof Systems. Let’s secure a durable, energy-efficient roof that protects your property for decades to come.