flat roof coating contractors sugar land tx: Trusted 2025

Why Professional Flat Roof Coating is Essential in Sugar Land’s Challenging Climate

Flat roof coating contractors sugar land tx are essential in a climate defined by more than just heat. Sugar Land’s humid subtropical climate delivers an average of 50 inches of rain annually, often in intense downpours that overwhelm drainage systems. This, combined with intense summer UV radiation that can push dark roof surface temperatures above 160°F and high year-round humidity that encourages algae and mildew growth, creates a uniquely hostile environment for flat and low-slope roofs. These combined forces accelerate the degradation of common roofing materials—weakening TPO seams, shrinking EPDM membranes, and stripping protective granules from modified bitumen surfaces.

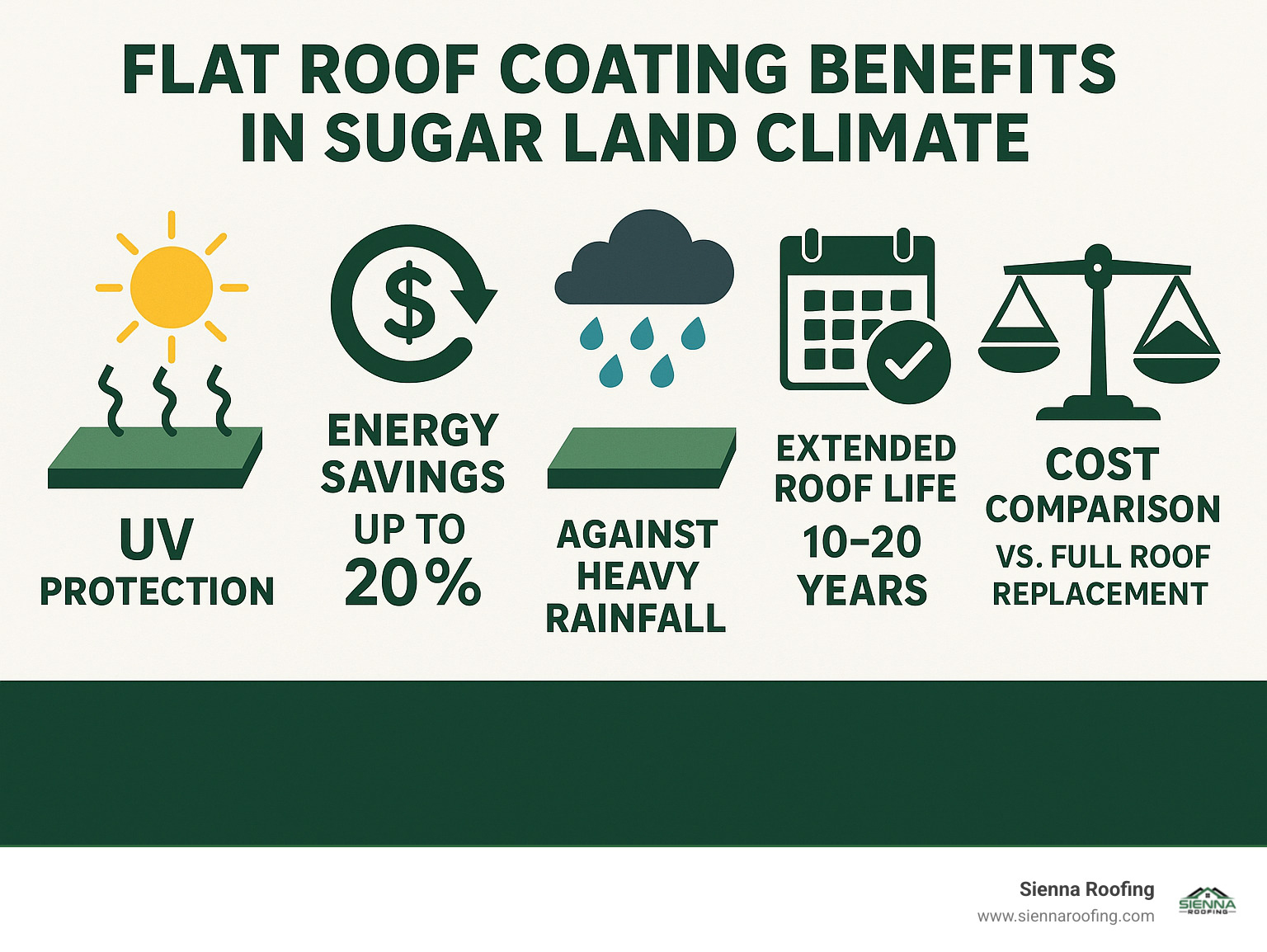

As a premier provider of roofing services in Sugar Land, we witness these challenges firsthand. A professional roof coating is not a temporary fix; it’s an engineered, monolithic shield against UV damage and water infiltration. It can lower rooftop temperatures by over 50°F, reduce energy use by up to 20%, and add years of durable, leak-free service life to your existing roof, making it a vital investment for any property owner in the region.

As the founder of Sienna Roofing, my background in Construction Management and years of local experience have shown why flat roof coating contractors sugar land tx must provide solutions that withstand our climate and deliver long-lasting protection for your property.

Common flat roof coating contractors sugar land tx vocab:

Why a Roof Coating is Your Best Defense Against the Sugar Land Climate

In the relentless Texas heat and humidity, your flat or low-slope roof is constantly battling the elements. From the sun’s UV rays to sudden downpours, the strain on roofing materials is immense. A high-quality roof coating acts as a proactive, protective layer that shields your roof from the daily wear and tear that leads to costly damage. Investing in a robust roof coating system is one of the smartest decisions a property owner in Sugar Land can make to safeguard their building and budget.

The Primary Benefits of Coating Your Flat Roof

A professional roof coating offers numerous advantages that directly address Sugar Land’s climate challenges. First, these coatings provide exceptional waterproofing. Flat roofs are prone to ponding water, a common cause of leaks and structural damage. A seamless, liquid-applied coating creates a monolithic membrane that prevents water infiltration, protecting your building’s interior. This is a game-changer for preventing common flat roof issues, saving you from the headaches and expenses of frequent repairs.

Beyond waterproofing, roof coatings significantly extend your existing roof’s lifespan by 10 to 20 years, helping you avoid a costly and disruptive full replacement. This is achieved through superior UV protection, which deflects the sun’s damaging rays and prevents material degradation, cracking, and blistering. This shield also reduces thermal cycling—the expansion and contraction of roofing materials due to temperature swings—a major cause of premature roof failure. By stabilizing roof temperatures, coatings maintain the underlying membrane’s integrity.

A Deeper Look at the Financial and Environmental ROI

While extending your roof’s life is a clear benefit, the financial and environmental returns on investment (ROI) are equally compelling.

Financial ROI: A full roof replacement is a capital-intensive project involving tear-off, disposal fees, new materials, and extensive labor. A roof coating project, by contrast, is typically classified as maintenance. This has two major financial advantages. First, the cost is significantly lower as you avoid tear-off and disposal costs, leveraging the asset you already have. Second, for commercial properties, IRS Section 179 often allows the full cost of a roof coating to be deducted as a maintenance expense in the year of completion, rather than being depreciated over decades like a replacement. This provides a substantial, immediate tax benefit.

Environmental ROI: Choosing a coating is also an environmentally responsible decision. Millions of tons of roofing waste are sent to U.S. landfills annually. By restoring your roof, you directly contribute to waste reduction. Furthermore, “cool roof” coatings are vital in mitigating the Urban Heat Island Effect. A reflective coating not only cools your building but contributes to a cooler community, reducing overall energy demand. The U.S. Environmental Protection Agency has documented the benefits of cool roofs in reducing energy use and air pollution.

How Coatings Boost Energy Efficiency and Savings

One of the most compelling benefits of modern roof coatings in a hot climate like Sugar Land’s is their contribution to energy efficiency. Many coatings feature “cool roof” technology with a highly reflective white surface. Instead of absorbing solar radiation and transferring heat into your building, the coating reflects it back into the atmosphere.

A traditional dark roof can reach temperatures over 150°F, but a reflective white coating can reduce that by 50-70°F. This dramatic temperature drop means a cooler building interior, so your air conditioning systems work less to maintain a comfortable climate. The reduced strain on HVAC units leads to lower energy consumption and utility bills, with some studies showing energy use can be reduced by up to 20%. This also extends the life of your HVAC equipment. For more information on how we can improve your roof’s protection, explore our dedicated roof coating services.

Choosing the Right Shield: Best Coating Types for Sugar Land Roofs

Selecting the right roof coating for your Sugar Land property is crucial for long-term performance. The best choice depends on your existing roof material, local conditions like ponding water or foot traffic, your budget, and desired lifespan. In our humid, sunny climate, UV stability and water resistance are paramount. Understanding the differences between coating types will help you make an informed decision.

Silicone vs. Acrylic: A Head-to-Head Comparison for Flat Roofs

Silicone and acrylic are two of the most popular and effective options for flat roofs, each with distinct characteristics suitable for different scenarios in Sugar Land.

| Feature | Silicone Coatings | Acrylic Coatings |

|---|---|---|

| Waterproofing (Ponding Water) | Excellent. Unaffected by ponding water, ideal for low-slope roofs where water might collect. | Good, but can re-emulsify (soften or break down) with prolonged ponding water. Best for roofs with good drainage. |

| UV Resistance | Excellent. Highly stable, resists degradation from intense UV rays, maintaining flexibility. | Excellent. Highly reflective and UV resistant, helping to keep roofs cool. |

| Durability | Very durable, retains flexibility across wide temperature ranges, and resists mildew. | Durable, but can become brittle in extreme cold (less of an issue in Sugar Land). May require more frequent recoating than silicone. |

| Flexibility | High. Maintains elasticity, allowing it to expand and contract with the roof’s movement. | Good. Flexible, accommodating some roof movement. |

| Cost | Generally higher upfront cost per gallon. | More cost-effective per gallon, making it a popular choice for budget-conscious projects. |

| Ideal Application in Sugar Land | Best for roofs with persistent ponding water issues or where maximum durability and longevity are desired. | Excellent for roofs with good drainage, where reflectivity and cost-effectiveness are key. |

Silicone coatings are solvent-free and known for superior water resistance, making them an excellent choice for flat roofs in areas with heavy rainfall. Their inorganic, moisture-cured chemistry means they are exceptionally resistant to degradation from UV radiation and do not become brittle or chalk over time. Acrylic coatings are water-based, highly reflective, and excellent at reducing heat absorption, contributing significantly to energy savings. However, their performance can be compromised by prolonged ponding water, making them better for roofs with efficient drainage.

Other High-Performance Options to Consider

While silicone and acrylic are prominent, other options may be suitable for specific needs in Sugar Land:

- Polyurethane Coatings: Known for exceptional durability and abrasion resistance, these are ideal for roofs with high foot traffic. They are often installed as a two-part system: an aromatic base coat for durability and an aliphatic top coat for high UV stability.

- Elastomeric Coatings: This broad category includes acrylics and other rubber-like materials designed to stretch and accommodate a roof’s natural expansion and contraction, preventing cracks.

- Liquid Rubber (EPDM) Coatings: These provide a seamless, highly flexible, and waterproof membrane with excellent UV resistance and durability, often lasting 10 to 20 years.

- Asphalt Coatings: A more traditional option, these offer balanced waterproofing, often used for restoring modified bitumen or built-up roofs, but typically lack the high reflectivity of other coatings.

Matching the Coating to Your Existing Roof Substrate

A successful coating project depends on compatibility with the underlying roof surface. Each substrate requires specific preparation and coating selection.

- Metal Roofs: Often develop rust and have many seams and fasteners that can leak. Prep involves rust removal/treatment and sealing every seam and fastener. Acrylic and silicone coatings are excellent choices.

- Single-Ply (TPO & EPDM): TPO can be challenging to adhere to and often requires a specific primer. EPDM must be thoroughly cleaned and may also need a primer. Silicone is often preferred for its excellent adhesion and flexibility on these surfaces.

- Modified Bitumen & Built-Up Roofs (BUR): These asphalt-based roofs require deep cleaning to remove loose granules. A ‘bleed-blocking’ primer is often necessary to prevent asphalt oils from staining the new coating. Both acrylic and silicone are effective.

- Concrete Roofs: Concrete is porous and must be fully cured, clean, and dry. Any cracks must be filled. Urethane coatings are often used for their durability and ability to bridge hairline cracks.

Consulting with experienced flat roof coating contractors sugar land tx is the best way to determine the most suitable system for your property. You can explore coating options from leading manufacturers like GAF to see the range of solutions available.

The Application Process: What to Expect from Professional Flat Roof Coating Contractors in Sugar Land TX

Applying a flat roof coating is a meticulous, multi-step process that requires professional expertise and precision. The success and longevity of the coating depend heavily on the quality of the application, especially the preparation phase. When you hire professional flat roof coating contractors sugar land tx, you can expect a systematic approach designed to ensure optimal performance and durability while minimizing disruption to your daily life.

Step 1: Meticulous Inspection and Preparation

This is the most critical phase of any roof coating project. Our technicians begin with a comprehensive inspection to identify any damage, weaknesses, or areas of concern. For a more advanced diagnosis, we can utilize infrared thermography to detect trapped moisture beneath the membrane that is invisible to the naked eye. Addressing these wet areas is critical before coating.

Once the assessment is complete, preparation begins:

- Thorough Cleaning: The roof surface is deep-cleaned using high-pressure power washers (up to 4,000 PSI) and specialized detergents to remove all dirt, chalking, algae, and oils that could inhibit adhesion.

- Repairs and Patching: All identified cracks, punctures, and damaged membranes are meticulously repaired. Any wet insulation is removed and replaced.

- Seam Reinforcement: Seams, flashings, and penetrations—the most common points of failure—are reinforced with specialized tapes or fabric-reinforced sealants to create a durable, flexible, and completely waterproof seal.

- Priming: Depending on the roof material and coating, a specific primer is applied to ensure optimal adhesion and prevent issues like bleed-through from asphalt roofs or delamination.

We believe that 75% of a successful coating project is in the preparation. Rushing this step can lead to blistering, peeling, and premature failure. Our commitment to meticulous prep ensures your coating stands the test of time.

Step 2: Flawless Application and Curing

After the roof is prepared, the liquid coating is applied using specialized spray equipment or rollers to ensure a uniform, seamless membrane. We pay strict attention to the manufacturer’s specified mil thickness. This is measured in ‘mils’ (one-thousandth of an inch) and is crucial for the coating’s performance and warranty coverage. We use gauges to measure both the Wet Film Thickness (WFT) during application and verify the final Dry Film Thickness (DFT) after curing.

The application typically involves multiple coats with adequate curing time between each layer, as specified by the manufacturer. Our team carefully monitors weather forecasts to schedule application during optimal dry conditions.

Step 3: Final Inspection and Warranty Activation

Once the coating has fully cured, our project manager conducts a final walkthrough. We check for uniform coverage, proper mil thickness, and ensure all detail work is flawless. We then provide you with all necessary documentation, including photos of the completed project and the activation of your manufacturer and workmanship warranties. This final step ensures you have total peace of mind in your investment.

How to Choose the Best Flat Roof Coating Contractors in Sugar Land TX

Choosing the right flat roof coating contractors sugar land tx will impact your roof’s performance for years. Look beyond price and focus on factors that indicate reliability, expertise, and a commitment to quality. A reputable contractor delivers a superior product and provides peace of mind through transparent communication and solid guarantees.

Key Factors for Vetting Flat Roof Coating Contractors in Sugar Land TX

To ensure you partner with the best, consider these factors when vetting contractors:

- Years in Business? Longevity in the industry often signifies stability, experience, and a proven track record.

- Are you licensed and insured in Texas? This is non-negotiable. Ask for a certificate of insurance and verify it. The contractor must carry both General Liability insurance to protect your property from damage and Worker’s Compensation insurance to cover their employees in case of injury. Without Worker’s Comp, you could be held liable for accidents on your property.

- Do you offer warranties (10-20 years)? A quality project comes with two types of warranties. The Manufacturer’s Warranty covers the coating material itself against defects. The Contractor’s Workmanship Warranty covers the quality of the installation. For larger commercial projects, ask about NDL (No-Dollar-Limit) warranties, which are the gold standard, covering both material and labor.

- Can you provide local references? A good contractor will be proud to share a list of recent, local clients. Call a few references and ask about their experience with the crew’s professionalism, communication, and how the roof has performed since the project was completed.

- Are you certified by manufacturers? Top-tier manufacturers like GAF require contractors to undergo rigorous training, demonstrate financial stability, and have a proven history of quality installations to become certified. A certified contractor can offer the best, longest-lasting warranties.

- What is your process for preparation and application? A detailed explanation of their process, especially emphasizing preparation and quality control checks like measuring mil thickness, shows a commitment to quality.

- What is their customer service philosophy? Look for companies that prioritize transparency, clear communication, and customer satisfaction. A commitment to excellent service makes a significant difference.

By asking these questions, you can significantly increase your chances of a successful project. You can learn more by reviewing our insights on 7 signs that a roofing company in Sugar Land is trustworthy.

Your Local Sugar Land Roofing Experts

At Sienna Roofing, we are proud to be your local flat roof coating contractors sugar land tx. We understand the specific climate challenges of Sugar Land, Missouri City, and Richmond because these are our homes too. Our commitment to personalized, community-driven service sets us apart.

We stand by our work with a 100% satisfaction guarantee. Our team has the experience to recommend and apply the most suitable flat roof coating system for your property, ensuring it stands up to the Texas elements for years to come.

You can find us conveniently located at:

Sienna Roofing

17034 University Blvd, Sugar Land, TX 77479

Phone: (832) 564-3322

We are dedicated to being among the most trusted roofing companies in Sugar Land, TX, and our track record speaks for itself.

Frequently Asked Questions about Flat Roof Coatings

We understand that investing in a roof coating brings up many questions. Here are concise answers to some of the most common inquiries we receive from property owners in Sugar Land.

What is the typical cost for flat roof coating in Sugar Land?

The cost for professional flat roof coating in Sugar Land typically ranges from $2.00 to $7.00 per square foot. This range is influenced by:

- Type of Coating Material: Silicone coatings tend to be more expensive than acrylics.

- Current Roof Condition: A roof requiring extensive repairs, cleaning, or primer will incur higher preparation costs.

- Size and Accessibility of the Roof: Larger or more complex roofs with numerous penetrations can increase labor costs.

- Labor Costs: The expertise of the flat roof coating contractors sugar land tx you choose plays a role. Certified contractors may charge more but provide superior application and warranties.

Despite these variables, a roof coating is a significantly more cost-effective alternative to a full roof replacement, which can easily cost two to three times as much.

How long does a roof coating last?

The lifespan of a flat roof coating depends on the material, application quality, and maintenance. In Sugar Land’s climate, professional application is key to longevity.

- Acrylic Coatings: Typically last 5 to 10 years.

- Silicone Coatings: Generally last 10 to 15 years due to high resistance to ponding water and UV degradation.

- Polyurethane Coatings: Can last 10 to 15 years, especially UV-stable aliphatic types.

- Liquid Rubber (EPDM) Coatings: Can offer an impressive lifespan of 10 to 20 years.

With professional application and proper maintenance, these coatings can meet or exceed their expected lifespan.

What is the difference between roof paint and a professional roof coating?

This is a critical distinction. Roof paint is a thin, standard exterior paint (3-5 mils thick) that offers minimal protection and breaks down quickly under UV exposure and ponding water. A professional roof coating is a thick, elastomeric membrane applied at 20-40 mils DFT. It is an engineered product designed for waterproofing, UV stability, and flexibility to move with the roof, providing long-term protection.

Will a roof coating fix my existing roof leaks?

No. A roof coating is a preventative and restorative membrane, not a patch for an existing problem. All active leaks, damaged seams, and areas of wet insulation must be professionally repaired before the coating is applied. Applying a coating over a leak will only trap moisture, leading to rot, mold, and eventual failure of the coating and the roof deck.

What maintenance is required for a coated roof?

While low-maintenance, a proactive approach will extend your coating’s life. We recommend bi-annual inspections, ideally in the spring and fall, to check for and address:

- Accumulated Debris: Leaves and branches can trap moisture and should be removed regularly.

- Minor Damages: Small punctures or tears from foot traffic or weather should be repaired promptly.

- Ponding Water: While some coatings handle this well, persistent standing water may indicate drainage problems that need addressing.

Occasional cleaning can help maintain the reflectivity of white coatings, preserving their energy-saving benefits. Proactive maintenance ensures your coated roof performs its best year after year.

Protect Your Investment with a Professional Roof Coating

In Sugar Land’s challenging climate, a professional flat or metal roof coating is a vital investment. These advanced coatings provide a multi-layered defense, extending your roof’s lifespan, preventing costly leaks, and significantly enhancing your building’s energy efficiency. Choosing the right coating system and ensuring it is applied with meticulous attention to detail by experienced flat roof coating contractors sugar land tx is the most important decision you can make for your property’s longevity. The benefits go far beyond a simple repair; it’s a strategic upgrade that delivers financial returns, environmental benefits, and long-term peace of mind.

At Sienna Roofing, we are dedicated to providing high-quality, sustainable roofing solutions custom to our community’s needs. Our 100% satisfaction guarantee means we work until your roof is performing optimally and protecting your property. Don’t wait for minor issues to become major expenses.

Take the proactive step to safeguard your property. Contact us today to schedule your free consultation and find how a professional roof coating can transform your roof into a durable, energy-efficient asset.