TPO Roof Replacement: 7 Critical Signs

Why TPO Dominates 40% of the Commercial Roofing Market

Choosing a TPO roof replacement is one of the most important decisions for your commercial building. Whether you manage a warehouse in Sugar Land or an office in the Houston area, understanding your options is key to protecting your business. As a leading provider of trusted commercial roofing in the Houston area, we’ve seen why Thermoplastic Polyolefin (TPO) roofing has captured 40% of the commercial market. This single-ply membrane offers an exceptional blend of durability, energy efficiency, and value for flat and low-slope roofs.

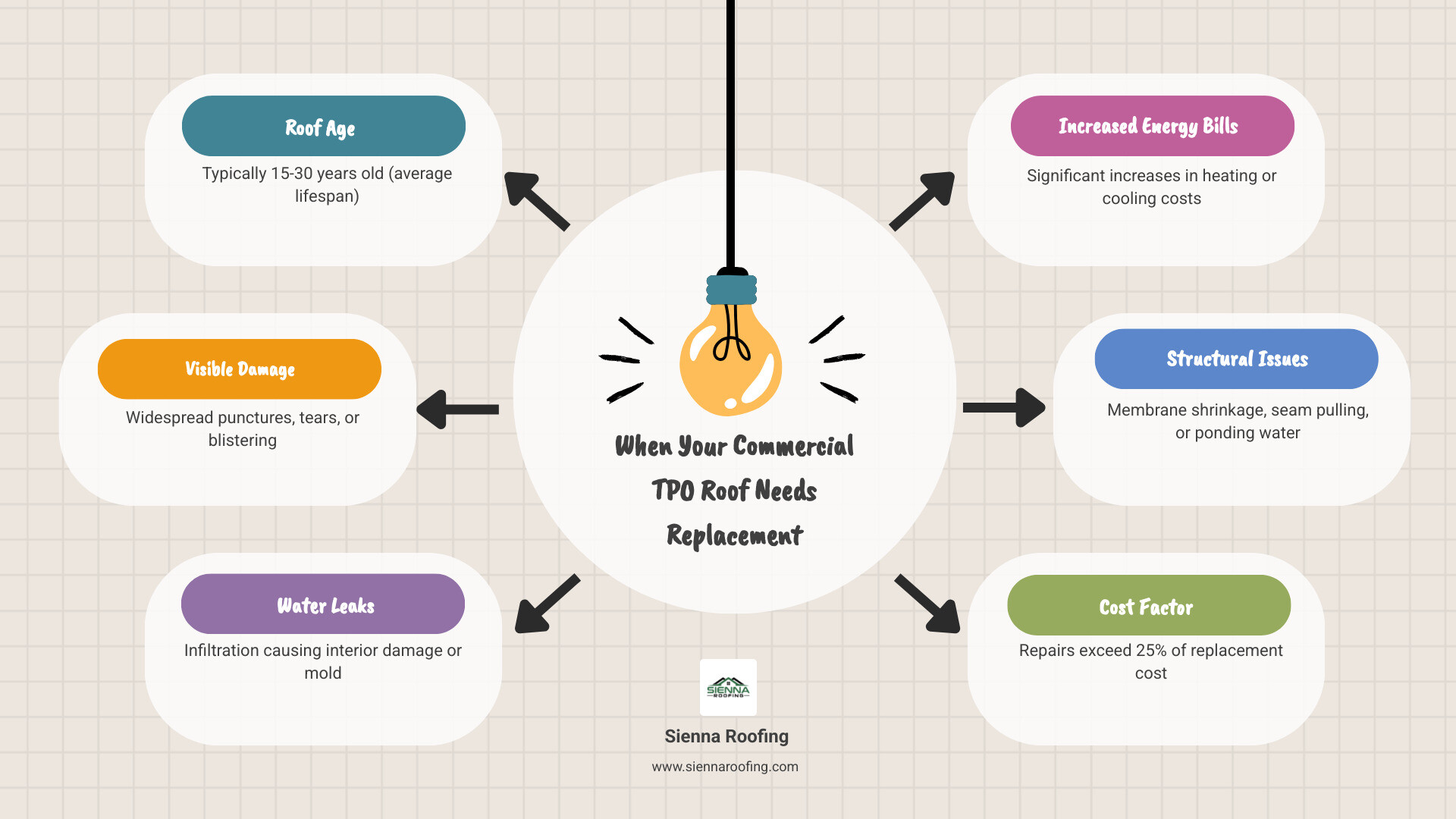

Quick Answer: When Does Your TPO Roof Need Replacement?

Your commercial TPO roof typically needs replacement when:

- Age: The roof is 15-30 years old.

- Damage: There are widespread punctures, tears, or blisters.

- Leaks: Water is infiltrating the building, causing damage or mold.

- Energy Loss: Heating or cooling costs have significantly increased.

- Structural Issues: Seams are pulling apart or water ponds for over 48 hours.

- Cost Factor: Repair costs exceed 25% of a full replacement.

A properly installed TPO system lasts 15 to 30 years and costs between $6 and $12 per square foot. However, when it reaches the end of its life, replacement is essential. I’m Andre Castro, founder of Sienna Roofing & Solar. With years of experience managing commercial TPO roof replacement projects in Sugar Land, I’ve created this guide to walk you through the process, from identifying warning signs to choosing a qualified contractor.

7 Telltale Signs Your Commercial TPO Roof Needs Replacement

Your TPO roof works hard to shield your business from Houston’s sun and storms, but even the most durable membrane will eventually show its age. Catching warning signs early can save you from emergency repairs, water damage, and operational disruptions.

Here are seven key indicators that it’s time for a TPO roof replacement:

- The Roof’s Age: While TPO roofs have a typical lifespan of 15-30 years, age is more than just a number. Constant exposure to Houston’s intense UV radiation breaks down the polymers and plasticizers that keep the membrane flexible. If your roof is approaching the 20-year mark, its materials are likely becoming brittle and less resistant to stress, making it vulnerable to failure even if it looks fine from the ground. Proactive replacement is often wiser than waiting for a catastrophic failure on an aging system.

- Visible Physical Damage: A visual inspection can reveal obvious signs of distress. Look for punctures from dropped tools or foot traffic, tears or gouges from flying debris during a storm, or blistering, which looks like bubbles on the surface where the membrane has delaminated from the substrate below. Even small breaches are significant, as they create a direct path for water to infiltrate the insulation, compromising its R-value and potentially leading to widespread moisture damage.

- Interior Water Stains: Water stains on ceiling tiles, discoloration on walls, or a persistent musty odor are undeniable red flags. This is the ‘iceberg effect’ in action: a small, visible leak inside often indicates a much larger, saturated area within the roof assembly. By the time you see damage inside your building, the problem on the roof is already advanced and requires immediate professional assessment to prevent structural damage and mold growth.

- Climbing Energy Bills: One of TPO’s key benefits is its energy efficiency, thanks to its highly reflective white surface. If you notice a significant, unexplained spike in your cooling costs, it could be a sign that your roof is failing. Over time, the membrane can accumulate dirt, debris, or biological growth like algae, which darkens the surface and reduces its reflectivity. More critically, if the underlying insulation has become wet, it loses its thermal resistance (R-value), forcing your HVAC system to work much harder to maintain a comfortable temperature.

- Separating Seams and Flashing Failures: The seams where TPO sheets are heat-welded together are designed to be the strongest part of the roof. However, due to membrane shrinkage from age and thermal cycling, these seams can come under tension and begin to pull apart. Likewise, the flashing around penetrations like HVAC units, vents, and drains is a high-stress area. Widespread seam separation or flashing failure is a critical issue that compromises the entire waterproofing system and is a primary driver for a full replacement.

- Ponding Water: A flat roof should never be a swimming pool. If you see water standing on your roof for more than 48 hours after a rainstorm, it’s a clear sign of inadequate drainage. This ‘ponding water’ is a roof killer. It accelerates the degradation of the TPO membrane, can weaken seams, and adds significant weight to your building’s structure—water weighs about 5.2 pounds per square foot for every inch of depth. This can lead to deck deflection and, in worst-case scenarios, structural failure.

- Bubbling, Wrinkling, or ‘Alligatoring’: Surface irregularities are a bad sign. Bubbles and blisters indicate that air or moisture is trapped between the membrane and the substrate, a sign of adhesive failure or a leak. Wrinkles often point to membrane shrinkage, which puts stress on seams. You may also see a pattern of cracking that resembles alligator skin, known as ‘alligatoring,’ which is a sign that the membrane has become brittle and is at the end of its life. All these conditions create weak spots that can easily be punctured or torn, compromising your roof’s integrity.

When to Repair vs. When to Replace Your TPO Roof

The decision to repair or replace often comes down to a cost-benefit analysis centered on one critical factor: insulation saturation. A professional roofer uses tools like an infrared scanner or core sampling to detect trapped water beneath the membrane that is invisible to the naked eye. This data is crucial for making an informed decision.

- Repair: If your roof is relatively young (under 12-15 years), the damage is localized (e.g., a few punctures or a single open seam), and an infrared scan confirms less than 25% of the underlying insulation is wet, targeted repairs are a cost-effective solution. A professional repair can extend the life of your roof for several more years.

- Replace: A full TPO roof replacement is the only logical choice when the damage is widespread, seams are failing in multiple locations, or more than 25% of the insulation is saturated with water. At this point, the system’s integrity is compromised. A common rule of thumb is if the total cost of repairs approaches or exceeds 25-30% of the cost of a full replacement, the replacement offers far better long-term value and peace of mind.

The TPO Roof Replacement Process: A Step-by-Step Guide

A successful TPO roof replacement is a systematic process that requires expertise at every stage. At Sienna Roofing, we’ve refined our approach over hundreds of projects in the Houston area to ensure quality and longevity. Here’s what you can expect:

-

Professional Inspection and Planning: A successful replacement begins long before the first roll of TPO is laid. We start with a comprehensive on-site assessment. This includes a visual inspection of the membrane, seams, and flashings; core sampling, where we cut small sections to analyze the layers of the existing roof system and check for moisture; and an infrared thermography scan to create a ‘map’ of any trapped moisture in the insulation. We also inspect the structural deck for damage. This detailed analysis allows us to create a precise project plan and scope of work that complies with Houston-area building codes and minimizes costly surprises.

-

Substrate Preparation (Tear-Off vs. Overlay): Based on the inspection, we determine the right approach. A complete tear-off is required if an infrared scan reveals over 25% insulation saturation, if the existing roof deck is damaged, or if building codes prohibit adding another layer (most jurisdictions allow a maximum of two roofing systems). While more intensive, a tear-off allows us to repair the structural deck and install a completely new, high-performance system. For structurally sound roofs with minimal moisture, a recover or overlay can be a cost-effective alternative. In this process, we install a new cover board directly over the existing roof to create a clean, smooth substrate for the new TPO membrane, saving on labor and disposal costs.

-

Insulation and Membrane Installation: With the substrate prepared, we install new rigid insulation boards, typically Polyisocyanurate (Polyiso), which offers a high R-value for improved energy efficiency. We can use a tapered insulation system to create positive slope, actively directing water toward drains and eliminating ponding issues. The TPO membrane is then installed using one of two primary methods: mechanically fastened, where screws and plates secure the membrane to the deck (a cost-effective and fast method), or fully adhered, where the membrane is glued to the substrate with a bonding adhesive. A fully adhered system provides superior wind uplift resistance and a smoother, more aesthetic finish.

-

Seam Welding and Detailing: This is where craftsmanship truly matters. We use robotic hot-air welders for long, straight runs to ensure consistent temperature, speed, and pressure, creating a perfect monolithic bond. For detailed areas like corners, pipes, and curbs, our certified technicians use hand welders to meticulously fuse the TPO membrane. This process creates a seamless, waterproof barrier that is stronger than the membrane itself. We then probe every inch of every seam with a specialized tool to confirm its integrity. Flashing details around HVAC units, vents, and perimeters are executed with the same precision, as these are the most common sources of future leaks.

-

Final Inspection and Quality Control: Before demobilizing from the site, our project manager conducts a rigorous final review. We walk the entire roof, inspecting every seam, flashing detail, and penetration to ensure the installation meets or exceeds manufacturer specifications. We create a ‘punch list’ of any minor adjustments needed and ensure the site is cleaned thoroughly. This final quality control check is our commitment to you, ensuring your new TPO roof replacement will protect your business for decades to come and that the manufacturer’s warranty will be honored.

TPO vs. The Alternatives: Making an Informed Decision

When considering a TPO roof replacement, it’s wise to compare it with other common materials to ensure it’s the best fit for your building. While TPO’s 40% market share speaks to its balanced performance, PVC and EPDM offer different strengths.

This table provides a clear comparison of the three leading single-ply membranes:

| Feature | TPO (Thermoplastic Polyolefin) | PVC (Polyvinyl Chloride) | EPDM (Ethylene Propylene Diene Monomer) |

|---|---|---|---|

| Cost (per sq ft) | Moderate ($7-$12) | Higher ($8-$15) | Moderate ($6-$10) |

| Lifespan | 15-30 years | 20-35+ years | 30-40+ years |

| Durability | Good (puncture/tear resistant) | Excellent (chemical/fire resistant) | Very Good (flexible, hail resistant) |

| Energy Efficiency | Excellent (highly reflective white) | Excellent (reflective white) | Poor (typically black, absorbs heat) |

| Seam Strength | Excellent (heat-welded) | Excellent (heat-welded) | Good (adhered/taped) |

| Chemical Resistance | Moderate | Excellent | Good |

Why TPO Often Wins: TPO delivers exceptional value by combining the durability and heat-welded seams of PVC with a more attractive price point. Its white, reflective surface is a major advantage in the Texas heat, significantly lowering cooling costs and helping reduce the urban heat island effect. TPO is also recyclable and often meets ENERGY STAR standards for cool roofs.

Where TPO Falls Short: TPO’s primary limitation is its moderate resistance to chemicals. For restaurants with grease vents or industrial facilities using harsh chemicals, PVC is often a better choice due to its superior chemical resistance.

Is a Roof Restoration a Viable Alternative?

If your roof’s structure is sound and insulation saturation is below 25%, a restoration can be a smart alternative to a full TPO roof replacement. This process can add 10-20 years of life to your roof at 40-50% of the replacement cost.

- Silicone Restoration: After cleaning and repairing the existing TPO surface, we apply a liquid silicone coating that cures into a seamless, highly reflective, waterproof membrane.

- Spray Foam Roofing: We spray a continuous layer of polyurethane foam over the prepared roof, which is then coated with a protective layer. This creates a seamless, highly insulated system.

Restoration avoids the cost, disruption, and landfill waste of a tear-off, making it an attractive option for qualifying roofs.

Budgeting for Your TPO Roof Replacement: Costs & Key Factors

Understanding the cost of a TPO roof replacement is crucial for business planning. In the Houston area, expect to invest between $6 and $12 per square foot, including materials and labor. For a 20,000-square-foot commercial roof, this translates to a project cost of $120,000 to $240,000.

This range is wide because several factors influence the final price:

- Roof Size and Complexity: While a larger roof has a higher total cost, its price per square foot is often lower than a smaller roof due to economies of scale. Complexity is a major driver; a simple, wide-open roof is far less expensive than one cluttered with numerous HVAC units, vents, pipes, and skylights. Each penetration requires extensive, labor-intensive flashing work to ensure a watertight seal.

- Deck Condition and Type: The condition of the structural deck beneath the old roof is a significant variable. If a tear-off reveals rotted wood, rusted metal, or crumbling concrete, these sections must be repaired or replaced, adding to the project cost. The type of deck (wood, steel, or concrete) also influences the installation method and cost.

- Material Choice (Thickness and Insulation): TPO membrane thickness is measured in ‘mils’ (one-thousandth of an inch). While 45 mil is a basic option, we typically recommend a minimum of 60 mil TPO for its superior puncture resistance and longevity. For high-traffic roofs or those in harsh environments, 80 mil TPO offers maximum durability. Similarly, increasing the thickness or R-value of the Polyiso insulation will increase material costs but deliver significant long-term energy savings.

- Installation Method (Tear-Off vs. Overlay): A complete tear-off is more labor-intensive and expensive due to demolition, debris disposal, and the need for deck repairs. An overlay is faster and cheaper but isn’t always an option. Similarly, a fully adhered system costs more in labor and materials than a mechanically fastened one but offers a cleaner look and better wind uplift performance.

- Accessibility and Logistics: If your building is tall or has limited ground access, a crane may be needed to lift materials and remove debris, adding a significant logistical cost to the project. Site safety requirements and managing operations to minimize disruption to your business can also influence the final price.

- Warranty Level: The best manufacturer warranties, such as a 20-year No Dollar Limit (NDL) warranty, cost more upfront. This premium warranty covers both materials and labor for the full term without depreciation and requires a more rigorous installation and inspection process. While it adds to the initial investment, it provides the ultimate long-term protection.

For a more detailed breakdown, see our complete guide to roof replacement costs.

Understanding Your TPO Roof Replacement Warranty

A quality TPO roof replacement includes two warranties:

- Manufacturer’s Warranty: This warranty covers defects in the TPO roofing materials. They range from 10 to 30 years. It is crucial to understand the difference between a ‘material-only’ warranty and a full system warranty that includes labor. The gold standard is a non-prorated, No Dollar Limit (NDL) warranty. ‘Non-prorated’ means the coverage doesn’t decrease over time, and ‘No Dollar Limit’ means the manufacturer will pay whatever it costs to bring the roof back into compliance. Be sure to read the fine print for exclusions, which often include damage from ponding water, unauthorized alterations, or lack of routine maintenance.

- Contractor’s Workmanship Warranty: This is arguably the more important warranty, as most roof failures are due to installation errors, not material defects. This warranty, typically lasting 5-20 years, covers any issues arising from the contractor’s labor, such as improper seam welding or faulty flashing. A contractor’s warranty is only as good as the company behind it. If they go out of business, your warranty is void. This is why choosing an established, reputable company like Sienna Roofing is paramount.

The most important factor for validating any manufacturer’s warranty is hiring a certified installer. Manufacturers like GAF, Firestone, and Carlisle will only issue their best warranties if the roof is installed by a contractor they have personally trained and certified. This certification ensures the contractor adheres to their strict installation specifications, which is your best guarantee of a long-lasting, high-performance roof.

Finding a Qualified TPO Roofing Contractor in the Houston Area

Choosing the right contractor is as critical as selecting the right material for your TPO roof replacement. A premium TPO membrane will fail if not installed by an expert. For businesses in Sugar Land, Missouri City, and Richmond, a local, reputable company is your best asset.

Look for these essential qualifications in a roofing contractor:

- Manufacturer Certifications: This is non-negotiable. Certification from manufacturers like GAF or Firestone proves the contractor is trained to their standards and is required to validate the manufacturer’s warranty.

- License and Insurance: Verify the contractor holds a valid Texas license, comprehensive liability insurance, and worker’s compensation to protect your business from liability.

- Local Experience: A contractor with a proven track record in the Houston area understands our unique climate challenges and local building codes.

- Detailed Written Contracts: A professional provides a detailed contract outlining the scope of work, materials, timeline, costs, and warranty information. Never rely on a verbal agreement.

- Transparent Communication: A good partner communicates clearly, answers questions thoroughly, and keeps you informed throughout the project.

At Sienna Roofing, we are the trusted choice for commercial roofing services in Sugar Land. Our team is fully certified, licensed, and insured. We built our reputation on personalized, community-driven service, and we treat your business as if it were our own. Call us at (832) 742-9922 to discuss your project.

Conclusion: Secure Your Business with a High-Performance TPO Roof

A TPO roof replacement is a critical investment in your commercial property’s longevity and security. TPO has earned its place as a market leader by offering a powerful combination of durability, cost-effectiveness, and energy efficiency that is ideal for the Texas climate.

Recognizing the signs of roof failure—from age and leaks to rising energy bills—is the first step. While repairs or restoration can be viable for roofs in good structural condition, a full replacement is the only reliable long-term solution for widespread damage or systems at the end of their service life.

The success of your project hinges on a meticulous installation process and, most importantly, the selection of a qualified, manufacturer-certified contractor. For businesses in Sugar Land, Missouri City, and across the Houston area, Sienna Roofing provides the expertise and community-focused service needed to protect your asset.

For expert guidance on your commercial roofing project in Sugar Land, contact our team today. Let us help you secure your business with a roofing solution that delivers peace of mind and lasting value.